|

|

| |||||||||||

| |||||||||||

How to do well in Assembly?

Date:2016-08-01

In PCB Assembly, there is a set of processthat is constantly being followed. One process cannot be skipped; one cannot beswitched to be performed over the other. For an SMT component populated PCB, itis always going to be the following processes (arranged in order):

Solder paste printing

Automatic placement

Reflow

But even if the processes are followed,certain problems arise when a populated PCB is inspected. In here, we are goingto tackle some of the PCB Assembly problems that are commonly encountered anddiscuss how to solve and prevent from happening again:

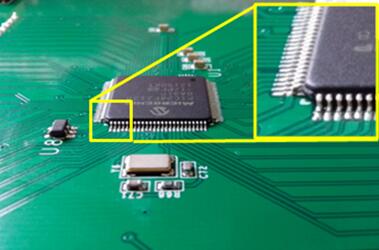

Solder bridging

Solder bridging is a phenomenon where atleast two neighbouring component pins have short circuited by way of anunnecessary solder. This phenomenon may be due to the following: excess soldervolume, inaccurate placement of the machine, or the plain mismatch of the PCBfootprint. To solve this problem, the engineers or assemblers should do thefollowing: reduce the solder volume by changing the printing machine settingsor go far as changing stencil mask opening.

2. Coplanarity

Coplanarity is a PCB Assembly problem thatcan be solved easily. This is mainly caused by a physically damaged component.But the cause of the damage will be difficult to find. It may be due to thedamage coming from the component supplier or a damage induced by the automaticplacement machine during the pick and place process. Either way, the focus ofthe investigation should only be concentrated on the component itself.

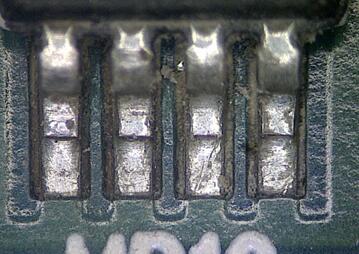

3. De-wetting

De-wetting is a solder anomaly wherein thecomponent pins don’t have enough solder creeping (wetting) around it. Itis also a common PCB Assembly problem. This may be caused by thefollowing: insufficient solder volume or mismatch of PCB footprint against thecomponent. To solve this problem, the engineer and/or the assembler must do thefollowing: change the solder volume deposit by changing the solder pasteprinting machine setting or change the stencil mask opening or change the PCBfootprint itself so it will match with component pins.

| Special |

|

| About us |

| Prodcuts List |

| Our Capability |

| Factory Tour |

| Information |

| Contact us |

| News |

|

| How to do well in Assembly? |

| 2016-08-01 |

|

| Notice when you design the Multilayer PCBs |

| 2016-05-26 |

|

| Our Location | ||||||

| ||||||

| ||||||